Project REGOLITH CRAFT — Reimagining Vernacular Masonry for Lunar Habitats

Project REGOLITH CRAFT explores how traditional masonry culture, especially in volcanic regions such as Rome, Syria, and the Canary Islands, can be reinterpreted for building permanent human habitats on the Moon. Rather than treating a lunar base as a purely engineering object, the project asks how “craft” and architectural knowledge might guide in-situ construction using lunar regolith as the primary material.

Lunar regolith is a fine, abrasive mixture of crushed basalt, glass, and mineral particles that blankets the Moon’s surface. Its properties are radically different from terrestrial desert sand, but they are structurally promising: it can be sintered or fused at high temperatures, it provides excellent radiation shielding when used in thick layers, and it can be processed into bricks, tiles, or glass. In the absence of an atmosphere, water-based binders such as concrete or ice mortar simply sublimate and cannot be used. At the same time, the Moon’s low gravity (about one-sixth of Earth’s) reduces self-weight loads on masonry structures, making thick stone-like walls more feasible.

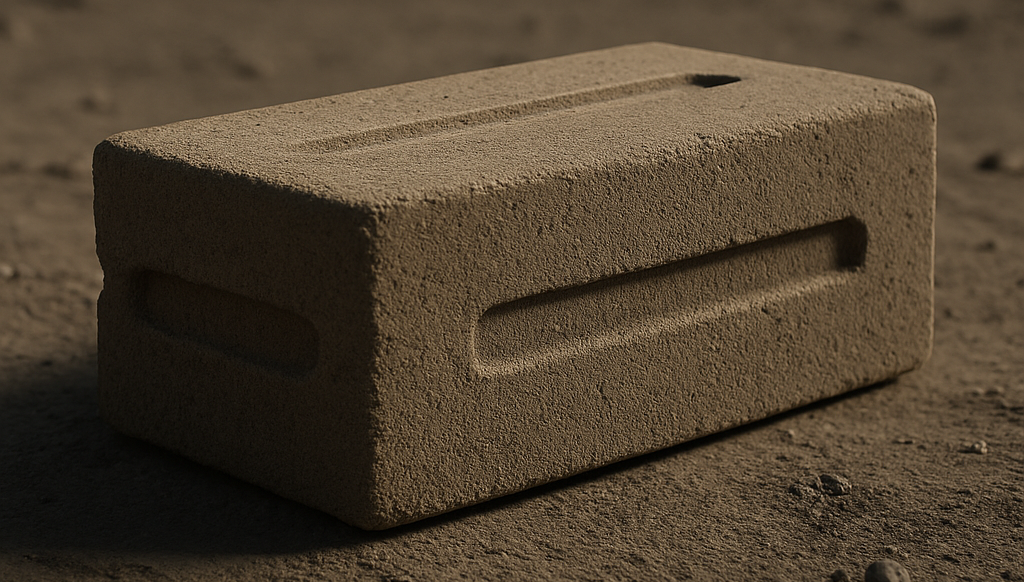

Current lunar construction concepts often assume large-scale 3D printing of regolith. However, in a dusty vacuum environment, nozzle clogging, contamination of moving parts, and the need for massive gantry systems pose significant reliability risks. These systems are difficult to repair on-site, and a single failure mode can halt the entire construction process. REGOLITH CRAFT proposes a different paradigm: instead of “printing” entire shells, we mass-produce simple elements—fired regolith blocks—and assemble them in a way that is robust, legible, and compatible with both human and robotic builders. In other words, the project brings the logic of brickwork and stone vaults into an extraterrestrial context.

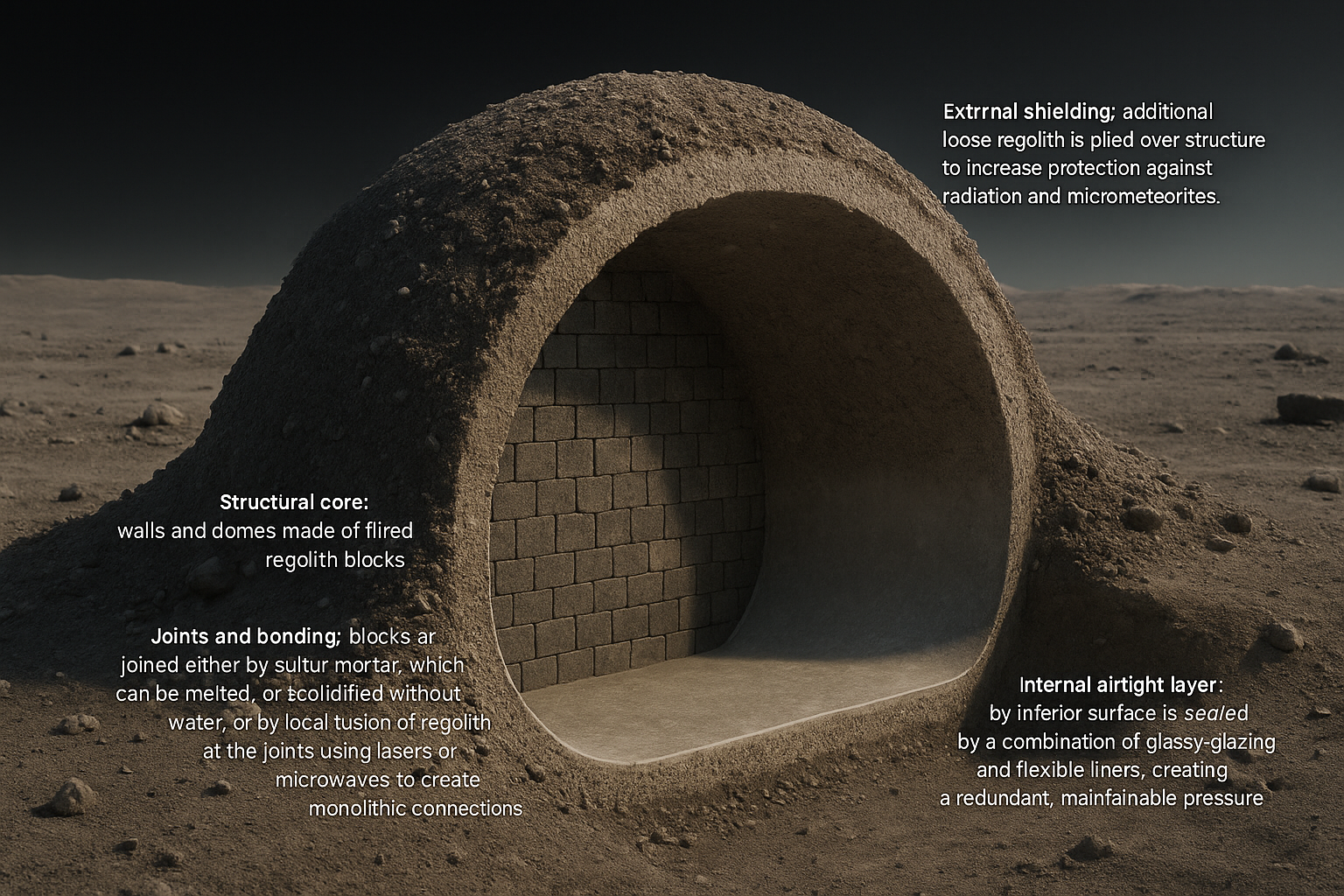

The proposed structural system is based on four layers:

- Structural core: walls and domes made of fired regolith blocks, analogous to basalt stone masonry.

- Joints and bonding: blocks are joined either by sulfur mortar, which can be melted and solidified without water, or by local fusion of regolith at the joints using lasers or microwaves to create monolithic connections.

- External shielding: additional loose regolith is piled over the structure to increase protection against radiation and micrometeorites, and to moderate temperature swings.

- Internal airtight layer: the interior surface is sealed by a combination of glassy glazing and flexible liners, creating a redundant, maintainable pressure boundary.

A key challenge is airtightness without conventional wet plasters. Instead of “applying” plaster with a trowel, the inner surface of the regolith wall is locally melted to a depth of 1–3 mm to form a continuous glassy skin. This process, inspired by ceramic glazing and traditional polished plaster, is carried out not by humans but by robotic arms equipped with high-temperature tools. The result is a smooth, dust-sealed surface that reduces air leakage and mitigates the dangerous regolith dust problem.

Because a single brittle layer is vulnerable to cracks, the project introduces a second, more flexible airtight layer. Drawing from cured-in-place pipe (CIPP) technology on Earth, the design uses an inflatable liner—such as a resin-impregnated textile or a multi-layer polymer/metal foil tube—that is unfurled inside the masonry shell, inflated to press tightly against the glassy surface, and then cured or mechanically locked in place. This liner becomes the primary pressure boundary, while the glassified regolith wall serves as a secondary seal and structural support. The combination creates a system that is both repairable and inspectable from the inside.

The baseline construction sequence is as follows:

- Excavate and process regolith, including sieving and particle size control.

- Fire regolith in a compact kiln system to produce standardized masonry units.

- Use semi-autonomous construction robots to stack blocks into walls and domes, following simple, rule-based bonding patterns similar to historical stone vaulting.

- Bond blocks using sulfur mortar or localized fusion at the joints.

- Perform interior glazing: robotic arms melt and smooth the inner surface to create a continuous glass-like layer.

- Install the inflatable liner (CIPP-style or multi-layer foil), inflate and cure it to achieve a smooth, pressurized interior.

- Conduct helium leak tests; repair defects by local re-melting or patching of the liner.

- Install interior partitions, life-support systems, and infrastructure.

Architecturally, the project explores three main typologies: domes, semi-buried vaults, and tubular modules that can be connected over time. Domes offer efficient load distribution and symbolic presence; semi-buried configurations exploit the regolith mass for thermal and radiation buffering; and tubular segments allow incremental expansion as new rooms and programs are added. For each typology, the project couples simplified structural calculations (wall thickness vs. internal pressure vs. material strength) with spatial scenarios for living, working, and communal gathering.

Beyond technical feasibility, REGOLITH CRAFT is a proposal about continuity of building culture. It imagines the emergence of “lunar masons” and “lunar plasterers” whose tools are lasers and robots, but whose logic of stacking, bonding, and finishing surfaces still echoes millennia of terrestrial architecture. The project positions lunar habitation not only as a frontier of aerospace engineering, but also as an opportunity to rethink how craft, environment-specific vernaculars, and local materials can shape the identity of off-world settlements.

As a next step, the project can evolve in three directions:

– Material and structural prototyping using regolith simulant, sulfur binders, and glazing techniques to test strength, airtightness, and reparability.

– Robotic construction workflows that choreograph simple, rule-based masonry operations instead of relying solely on large-scale 3D printing.

– Physical and digital modeling that makes the relationships between wall thickness, radiation shielding, and inhabitable space legible to both designers and non-experts.

Ultimately, Project REGOLITH CRAFT asks how traditional architectural intelligence—developed in volcanic landscapes on Earth—might guide the way we build durable, meaningful habitats on the Moon.